HOW TO CHOOSE A RIGHT DRILL BIT

DRILL BIT MATERIALS

High-Speed Steel (HSS) is a popular material good for drilling into soft steels as well as wood and plastic. IT’s an economical solution for most maintenance drilling applications.

Cobalt (HSCO) is considered an upgrade from HSS because it includes 5-8%Cobalt blended into the base material. This is a great option for drilling into harder steel as well as stainless steel grades.

Carbide (Carb) is the hardest and most brittle of the drill bit materials. It’s used mostly for production drilling where a high-quality tool holder and equipment is used. It

should not be used in hand drills or even drill presses. These drill bits are designed for the most demanding and hardest materials.

DESIGN FEATURES

DRILL POINT ANGLE

118°Standard -Found on most common drill types.

135°Self-Centering – This type will begin drilling faster, especially in stainless steel materials.

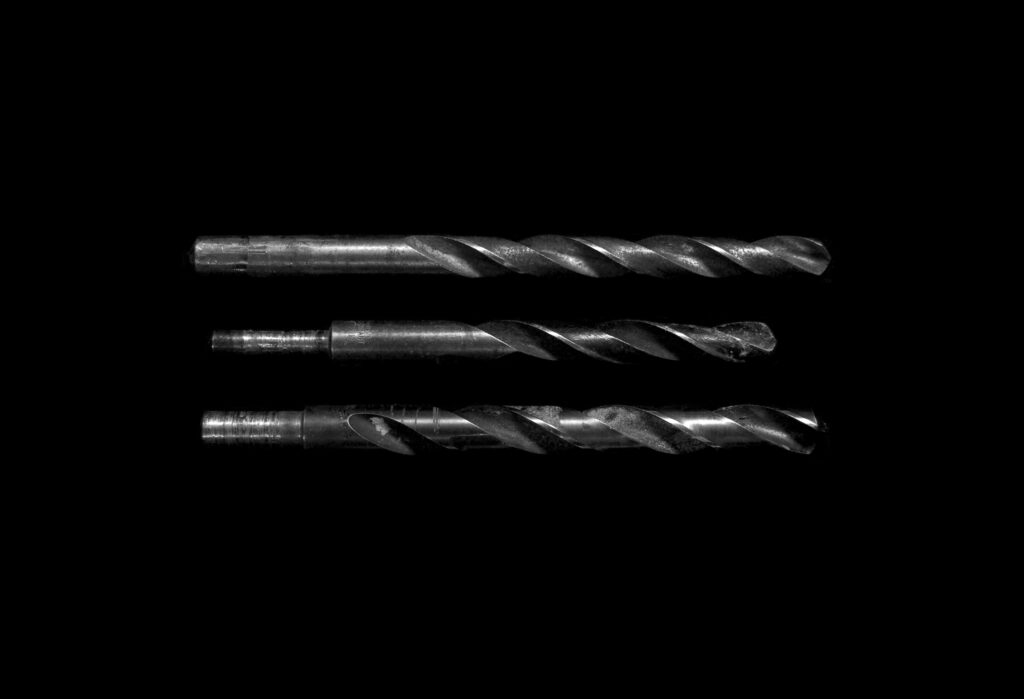

DRILL POINT LENGTHS

If a shorter drill bit can do the job, it’s a good option. Shorter drill bits are more accurate and because they’re more rigid they don’t break as often. This helps keep workers on task and the project on schedule. Shorter drill bits are also better in tighter, more confined areas.

FLUTE DESIGN

Standard – This is the most common with 30*angles

Parabolic Design – The open design helps chip removal out of the hole. These are especialy effective in very soft materials like plastics and aluminums.

DRILL POINT COATINGS

Black Oxide (surface treatment) Helps reduce friction and increase chip flow. Not for nonferrous materials.

Bright Not real finish, but polished for increased chip flow. For use in plastics, woods and aluminum.

TiN(titanium nitride, gold color) Can be run faster than uncoated drills and increased tool life.

TICN (titanium carbonitride, blue-gray color) Great for stainless steel, cast iron and aluminum. Harder and more wear-resistant than other coatings.TiALN(titanium aluminum nitride, violet color) For use in high-alloy carbon steels, nickel-based materials and titanium. Not used for aluminum.

Choosing the right drill bit for the task is an important part of any project or application. Whether it’s matching the appropriate bit to the substrate material, getting the right match for the depth and diameter of the hole, or even the volume of work needed, the right choice can extend the life of your drill bits. This in turn helps to improve productivity by allowing you to get more done with each drill bit.